|

RGB |

|

|

This project

is a DICE (DIE) made with 7 LEDs. Normally the LEDs are red or green,

but we have used RGB LEDs to produce an interesting display as well as

creating a number of other effects.

The project is built on Matrix Board with wiring created with fine

enamelled wire and the it comes with a

pre-programmed chip containing a number of different effects.

You can also program the chip yourself and use this project as the

beginning to: "learning to write your own programs."

RGB

LED DICE on

matrix board

The CIRCUIT

The project creates a number of effects on an RGB LED,

including PWM (Pulse Width Modulation) to show the effect of turning on

the LED(s) for a very short period of time then turn the LED(s) off for

a longer period of time. THE RGB LED SURFACE-MOUNT COMPONENTS

Underside of RGB LED

DICE showing SM

components

The PC track is cut just before the 221 SM resistor

and just after the 271 SM resistor (see note below).

Note the link using enamelled wire.

The 47k SM resistors are not needed as the

micro has 47k internal pull-up resistors enabled.

RGB

LED DICE Circuit

The circuit is very simple. It is

just 7 RGB LEDs, 2 switches a piezo diaphragm and 8 other components. All the work is done by the micro.

The diode reduces the 6v supply to 5.4v and also prevents reverse voltage

appearing on the chip.

This will reduce the brightness and also consume less current. When this

is done to all three LEDs a range of colours can be created. This

involves delivering a different percentage of ON-TIME for each LED to

produce a specific colour.

The major purpose for the introduction of the RGB LED was to produce a

wide range of colours, plus white.

This allows it to be used for screens such as TV screens, to reproduce

moving images.

Any sort of display requires a lot of LEDs and this requires many

drive-lines. A single 8-pin micro an only drive one or two LEDs and we

have opted to use a single LED and show the range of effects that can be

produced.

The RGB LED supplied in the kit is high-bright. It is

too bright to look at directly but can be used for all sorts of

applications and effects. You can reduce the brightness by increasing

the value of the current-limiting resistors to suit your own

application. The PWM sequences reduce the brightness and you can observe

how effective they are at reducing the current consumption. We have used

220R and 270R resistors to reduce the brightness so the output is

not too bright.

They also make the project look simpler as they "disappear" under the

board; or if you are developing a single-sided project, they reduce the

size of the final design.

You will need fine tweezers to hold

them in place while one end is soldered.

Always use very fine solder as you only need very little for each

component and the main reason for adding extra solder is to take advantage of

the flux to clean the connection. Always solder resistors with the value

showing.

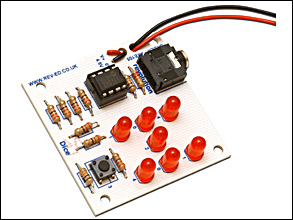

CONSTRUCTION

The RGB LED Dice

project is built on Matrix Board.

The kit of components comes with all the parts you need to get the

project working, including a pre-programmed chip and PC

board.

The parts are fitted

as shown in the photo above. When all the through-hole components have

been fitted, they are soldered in place and the leads cut off. Then the

surface-mount resistors are added to the underside of the board. In most

cases, one pad will already have solder and the resistor is fitted to

this pad first. Then the other end is soldered. You will have to hold

the resistor with tweezers while soldering the first end. Mae sure the

resistor code can be seen.

|

|

|

TESTING THE CIRCUIT

To assist in testing the

circuit, you may need a Logic probe. The RGB LED Dice circuit is

very simple and the following Logic Probe can be put together in less

than an hour. It will indicate HIGHs and LOWs as well as pulses.

The author did not need the Logic Probe to test the RGB LED Dice project

as the circuit worked the first time it was switched on.

However the circuit was tested by getting a 6v supply with 470R series

resistor and probing the pins of the 8-pin IC socket without the chip

being installed.

As each set of pins was tested, the corresponding colour illuminated to

prove the wiring was correct.

The author makes a point of only using a simply multimeter and a Logic

Probe to test any of the projects in this series because these are the

only pieces of test gear that will be available to the average hobbyist.

So, we have two areas of interest. Construction and Programming and

it's up to you to take it on.

The project is designed for all sorts of uses, including models such as

train layouts, alarms and similar effects.

But the real thing we want to get across, is programming.

This is another example of using a simple 8 pin chip to provide a number

of features that would take many logic chips (such as counters and gates) and lots of components to

duplicate.

It also highlights our method of hand-coding as an effective way to

produce a program.

This project uses about 400 instructions to produce the effects and it uses the EEPROM to store the sequence

produced by the user (sequence 1) - and show it at turn-on.

In this respect, some of the sub-routines in the program are quite complex and suitable

for the advanced programmer. However, if you are a beginner, you can

read through the program and most of the sub-routines will be easy to

follow as each line of code is explained. You have to start somewhere

and this project offers a challenge.

Most projects with a program of this complexity are only available as a

pre-programmed chip or only the hex code is available. There is usually no

attempt at educating the reader in programming.

That's the difference between our projects and all others.

We offer a learning curve.

For every hour of effort you put into reading, building and using one of

our microcontroller projects, you get the experience of 100 hours of

effort that has been put into the design to make it appear simple.

All you have to do is start . . .

|

INSTRUCTIONS FOR USE Press the "Roll Dice" button and the display will flash to give the impression of a rolling dice and will settle on a result. The second button produces a number of effects on the display. There are 5 different effects and each time the button is pressed a different effect will be displayed. |

PROGRAMMING THE

CHIP

The kit comes with a pre-programmed PIC chip but if you want to program

your own chip or modify the program, the .hex file is available as well

as the assembly file, so you can see how the program has been written

and view the comments for each line of code.

The PIC12F629 is one of the smallest micros in the range but you will be

surprised how much can be achieved with such a tiny micro.

The program contains sub-routines to produce delays, sequences on the

display and both read and write EEPROM jobs that require accurate code

- including a special sequence - called a handshaking sequence that

prevents the EEPROM being written due to glitches.

Even a program as simple as this is not easy to put together and to

assist in this area, we have provided a whole raft of support material.

Not only do we provide a number of programs with full documentation but

our approach to programming is simple.

It involves a method of "copy and paste" whereby sub-routines

are taken from previously written code and copied into your program. Any modifications are

made in very small steps so that each can be tested before adding more

code.

This is exactly how we produce a complex project. Each step is written

and tested before adding the next step.

This saves a lot of frustration as it is very easy to add a line

of code that is incorrect and get an unsuspected result.

If you follow our suggestions you will buy a programmer ("burner")

called a PICkit-2 if you are using a laptop. It is the cheapest and best on the market

and comes with

a USB

cable and 2 CD's containing the programs needed to "burn" the chip.

If you are using a desk-top and/or tower with a serial port, you can use

a cheaper programmer called MultiChip Programmer from Talking

Electronics. You

will also need NotePad2 to write your .asm program. This can be

downloaded from Talking Electronics website. You will use

RGB LED Dice.asm

or

RGB LED_Dice-asm.txt as a template for your

program, plus a 6 pin to 5 pin connector that fits between the burner

and the project. This is also available on Talking Electronics website.

As we said before, this project is for medium-to-advanced programmers as

it is very compact and does not have in-circuit programming pins.

To be able to modify the chip you will need a programming socket and

this can be obtained from one of our other projects that contains the 5

pins for in-circuit programming.

You can then put the chip into the other project to be programmed and

modified and re-fit it into this project for execution.

PROGRAMMING LANGUAGE

There are a number of kits, programs and

courses on the market that claim and suggest they teach PIC Programming.

Most of these modules and courses use a PIC microcontroller as the chip carrying out

the processes, but the actual programming is done by a proprietary

language invented by the designer of the course.

Although these courses are wonderful to get you into "Programming

Microcontrollers" they do not use any of the terms or codes that apply

to the PIC microcontroller family.

All our projects use the 33 instructions that come with the PIC

Microcontroller and these are very easy to learn.

We use the full capability of the micro and our pre-programmed chip is

less than the cost of doing it any other way.

In addition, anything designed via our method can be instantly

transferred to a PIC die and mass produced. And we use all the input

pins and all the memory of the chip. The other approaches

use less than 25% of the capability of the memory and one of the pins is not available.

In fact it would be difficult to reproduce this project via any of the opposition

methods. It would require a larger chip and more expense.

You can use our method or the opposition. Just be aware that the two are

not interchangeable.

Ours is classified as the lowest "form" (level) of programming - commonly called

machine code - invented in the early days of microprocessors - and now

called mnemonic programming as each line of code is made up of

letters of a set of words. The opposition uses a higher level language

where one instruction can carry out an operation similar to a

sub-routine.

But you have to learn the "higher level language" in order to create a

program. And this requires a fair amount of skill and capability.

It sounds great and it is a good idea. But if you want to learn PIC

programming, it does not assist you. It is "a step removed" from

learning PIC language. The other disadvantage of the opposition is the

"overhead." The 1,000 spaces allocated for your program is filled with

pre-written sub-routines. You may require only 10 of these sub-routines but ALL

of them are loaded in the memory space. And they take up all the memory.

You have no room for your own program.

To get around this the opposition uses the 128 bytes in EEPROM to deliver

instructions on how to apply the sub-routines. This provides about 30 powerful instructions using their

language called BASIC (or a similar language).

It's a bit like selling a diary filled with all the paragraphs you need

to express yourself, and leaving a few blank pages at the back for you

to write single lines such as: see page 24, paragraph 7, see page 63

paragraph 4, to create your diary entries.

It depends on how much you want to be in charge of writing a program. Using

our method is like writing your own auto-biography. Using the opposition

is like getting a "ghost writer."

When using a higher level language to create a program, you have absolutely no

idea how the code is generated for the micro.

In some of the developmental kits, the code is "locked away" and you are

NEVER able to access it.

Everything runs smoothly until a fault appears. With our method you can

see the code. With the other methods, you cannot see the code - it's

like doing key-hole surgery without the advantage of an

illuminated endoscope to see what you are doing.

Everything has its place and our method of hand-assembly is only

suitable for very small micros and you will eventually need to "learn a

high level language." The PIC12F629 has over 1,000 locations for code

and this equates to more than 20 pages when printed, so this is about

the limit to doing things by hand.

But our drive is to show how much can be done with the simplest devices

on the market, at the lowest cost.

Anyone can show you high-technology at a high price but this is not

where you start and this is not where you get enthusiasm.

We provide the things to get you started. That's the difference.

CHARLIE-PLEXING

MODIFYING THE PROGRAM

The

PROGRAM

HISTORY

When ever you invent a

product or idea, GIVE IT A NAME.

That's the first thing I do when I produce a new project.

It gives you a "point of reference."

And that's what has been done by the inventor of the circuit we have

used in this project.

It's called CHARLIE-PLEXING and

is basically the concept of

connecting as many LEDs as possible to the outputs of a micro.

Each output of a micro can deliver current (25mA) when it it HIGH and

sink 25mA when it is LOW.

This means it will illuminate a LED when two outputs are in particular

directions and another LED when the outputs are reversed.

With 3 outputs, 6 LEDs can be illuminated, but not all at the same time.

With 4 outputs, 12 LEDs can be connected and sometimes more than one LED

can be illuminated at the same time.

With our RGB LED Dice project, two LEDs are connected in parallel

(called Display LED "A" and "A+"), two

more LEDs are connected in parallel (called Display LED "B" and "B+") and two more LEDs are connected in

parallel (called Display LED "C" and "C+"). 9 leads are produced from these 6 LEDs.

The final LED (the centre LED of the display ("D") has 3 more leads. Thus we

have a total of 12 leads and by charlieplexing we can illuminate any of

the colours from any of the LEDs. We have already mentioned that

all the LEDs cannot be turned on at the same time, however sometimes

more than one colour can be turned on at the same time and this will be

discussed later.

We now come to another interesting feature.

The maximum current from each output of the micro is 25mA.

If you drive any of the colours of the RGB LEDs with 25mA,

the light output will be blinding. The LEDs will be far too bright to

view and the colours will be blurred.

We have a choice. We can drive them with 12mA or put 25mA through them

for 50% of the time. You would think this comes to the same brightness.

But no so.

Our eyes are non-linear and by delivering 25mA for 50% of the time,

produces a brightness almost equal to the full 25mA - so it is a much

more effective way of illuminating the display.

In fact we can reduce the time to about 10% and still produce a viewable

brightness. The reason is the LED comes on at full brightness @ 10% of

the time and our eyes see this peak and retain the brightness until the

next peak arrives. If we pulse the LED very quickly, the LED will appear

to be bright ALL THE TIME.

We need to employ this trick because we cannot turn on all the LEDs at

the same time. Depending on the LEDs we want to illuminate or the

effects we want to show, we may have up to 8 different colours being

illuminated, one after another.

All the complexities of how the colours are turned on has been worked out

and each number, from 1 - 6 has been placed in a separate sub-routine.

All you have to do is call the sub-routine and the appropriate colour

and particular set of "pips" on the display will be illuminated..

And the same applies to the effects. These are worked out separately and

placed in sub-routines.

There is only one simple rule to remember.

To turn on a colour in an RGB LED, one output has to be HIGH and the

corresponding output has to be LOW.

No other LEDs on these two outputs can be illuminated. However LEDs on

the other two outputs can be activated and if this can be done at the

same time, the display will be slightly brighter if it reduces the size

of the "run." This is the number of individual "illuminations" required

to produce an effect.

Very good brightness

can be achieved with a "run-of'-four" as the LEDs are high-bright.

You will notice that some of the unused colours inside the LEDs are connected to the

outputs we are driving and to prevent these

LEDs illuminating, the unused outputs are turned into INPUTS. This means

the line is neither high or low and is equivalent to the LED being

disconnected from that particular line.

The outputs can be changed to inputs at any time during the running of

the program and this gives us great flexibility with driving the

LEDs.

It is quite easy to work out which lines have to be made HIGH or LOW or

turned into an INPUT. Simply look at the circuit.

To modify the program you will need a PICkit-2 programmer and this comes

with 2 CD's containing all the software needed for In-Circuit

Programming.

You will also need a lead (comes with PICkit-2) to connect the programmer to your lap top via

the USB port and an adapter we call 6pin to 5 pin

Adapter to connect

the PICkit-2 to your project.

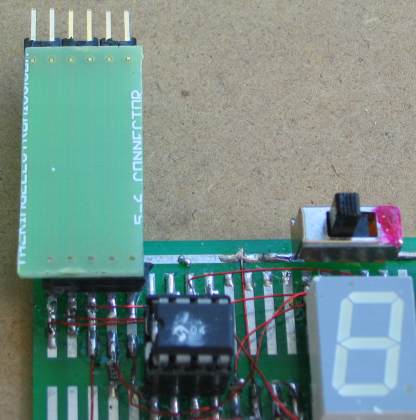

6pin to 5pin

Adapter

Adapter connected for In-Circuit Programming

(the chip is placed in another project for in-circuit

programming

or any PC board with 5 In-circuit Programming pins)

The program looks complex

because the LEDs are being accessed individually and each illumination

requires a separate sub-routine. Two LEDs marked "A" are in parallel,

two LEDs marked "B" are in parallel and two LEDs marked "C" are in

parallel. LED "D" is a single LED. This means the display is

limited to driving and illuminating these pairs of LEDs and you cannot

produce random effects on the display without taking these limitations

into account.

The program

does a bit of

detecting when turned on. It detects to see if a bit has been set in

EEPROM to tell the micro to go to a required sequence or start with

sequence 1.

It also detects if switch A or C has been pressed at the instant the

project is turned on so that the micro is directed to the sub-routine

where the user-sequence can be entered or if the EEPROM bit is to be

cancelled.

All this gets done in the SetUp routine and then the micro goes to Main.

In Main, the program increments a "jump" file and calls a table where it

finds a directive to go to a particular sub-routine.

The sub-routine is executed and the micro goes back to Main where it

looks for a release of SwA. This forms part of a key debounce as the key

must be fully debounced as it is advancing the micro through the

sequences.

To provide a totally reliable debounce, the key is detected as not being

pushed for the duration of a whole cycle of a sequence and a separate loop is then executed where the key can be

detected as being pushed, to advance the program to the next sequence.

To create your own sequence as sequence1, the project is turned off and

SwA pressed while turning the project ON.

This sends the micro to a sub-routine called Attract.

As soon as SwA is released, the program starts to time the duration when

a switch is not pressed and it "times-out" after 2.5 seconds.

The program also times the duration when a LED is illuminated. It also

accepts 2 or 3 LEDs illuminated at the same time. These are all clever

instructions that need to be looked at to see how they operate.

Up to 15 steps can be entered and each step occupies three bytes. The

first value identifies the illuminated LEDs, the second byte identifies

the ON duration (in increments of 5mS) and the third byte identifies the

OFF time.

These 45 bytes are contained in files 30h to 5Fh.

When a switch is not pressed for 2.5 seconds, the program "times out"

and sends the values to the EEPROM. It then shows the sequence on the

LEDs.

If the project is turned off and on again, this sequence will be

displayed as sequence1.

To replace the sequence with something else, simply repeat the steps above.

If you want one of the pre-programmed sequences to appear each time the

project is turned on, simply advance through the sequences by

pressing SwA and when the desired sequence is playing, push SwB.

This will record your choice. Turn the project OFF then ON again and the

chosen sequence will be displayed.

To remove this feature, press SwC when the project is off and at the

same time, turn the

project ON.

All these feature have been added to the program, one at a time, and it

is important to add them in the correct order. For instance, you can only add a removal feature after the

initial feature has been produced. Reading and writing to the EEPROM is

a most complex operation and the instructions must be laid out as shown

in the program, as they include a hand-shaking sequence. When you need this

code it is copied and

pasted in its entirety, to prevent a mistake.

Nearly every instruction has a comment to explain not only what it does, but why it was chosen.

To illuminate each set of LEDs, the

in-out resister (TRIS) must be loaded and the out lines must be taken

HIGH or LOW. Any line configured as an input is effectively removed from

the circuit and does not have any effect.

The first thing to do is create a sub-routine to drive each of the LEDs:

"A," "B," "C," and "D."

The produce a sub-routine that uses 1, 2 or 3 of the previous

sub-routines.

We have already mentioned the fact that the LEDs are too bright when

driven at 25mA and to reduce the brightness, a short delay much be

included.

As you increase the number of sub-routines, you will notice that

previous routines can be used and this saves a lot of space.

Programming is like owning a LEGO factory. As you introduce new

products, you can use many of the previously developed Lego blocks and

bricks.

Here are the files you will need:

RGB LED Dice.asm

RGB LED_Dice-asm.txt

RGB LED Dice.hex

;RGB LED DICE.asm

;****************************************************

;RGB LED FX.asm *

;25 sequences to demonstrate the possibilities for *

;an RGB LED *

;22-5-2011 *

;****************************************************

; 2100h

END

LED Dice projects have been

around for a long while.

The simplest circuit uses 6 LEDs and they get scanned by a CD 4017 chip.

This is not very impressive.

The next circuit uses a very interesting feature of the 4017 chip. The

"carry out" (pin 12) is HIGH for the first 5 clock pulses.

The following circuit uses a PIC12F629 to drive a 7-segment display. It

has the "slow down" feature.

The first output is pin 3, so that just pin 12 is HIGH and thus LEDs "B"

illuminate to produce "2" on the display.

The next output to go HIGH is pin 2 and this makes LEDs B and A

illuminate to produce "3" on the display. Using pin12 reduces the

complexity of the project while producing the "pips" on a dice.

This circuit shows the importance of reading a datasheet thoroughly and

understanding what is going on with the outputs of a chip. The circuit

does not have the "slow down" feature.

The next project uses a PICAXE-08 chip that is really a PIC12F629 but you do

not use any of the PIC instructions to create a program. You use

instructions created by the supplier of the chip and you are effectively

learning nothing about programming a PIC chip. The chip could be an Atmel or NEC or Philips microcontroller.

Here are 4 more LED Dice projects:

The

first photo shows a project using an oscillator chip and 4017.

The second photo uses a 555 a 4071 OR-gate and a 4017 counter. The

circuit is below. A few diodes can take the place of the 4071 chip

and the project is over-designed.

The third photo shows a microcontroller project using an Atmel

micro. The fourth photo shows a multivibrator made from 2

transistors and a 4017 chip.